Distributed Optical Fiber

Acoustic Sensing

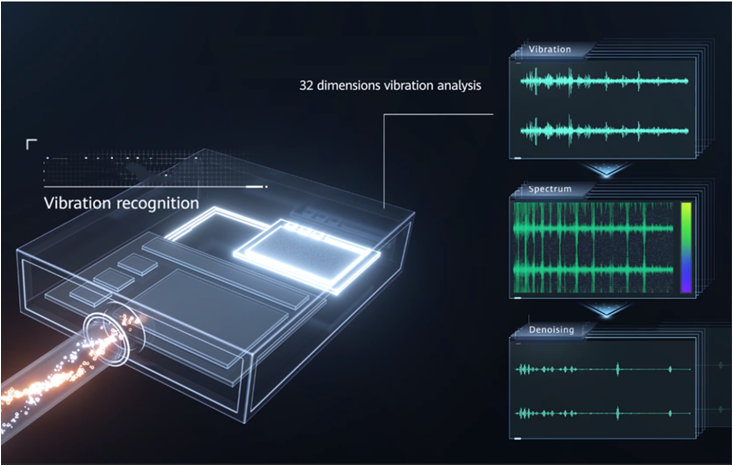

We utilize the optical fiber itself as both the transmission medium and the sensor. Through advanced Phase-Sensitive OTDR and Rayleigh scattering, we transform 5km of fiber into 2,500 distinct sensors.

- Precision: Measurement pulse spacing of just 2 meters.

- Passive: No electricity required along the belt line.

- Resilience: Immune to EMI and corrosion.